Horizontal multistage centrifugal pump material

Horizontal multistage centrifugal pump material

Horizontal multistage centrifugal pump material

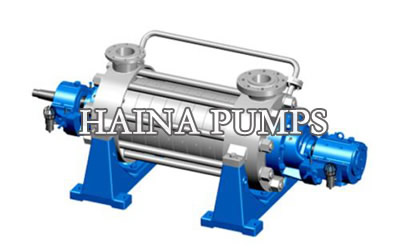

Horizontal multistage centrifugal pump is based on the principle of centrifugal force design, high-speed rotation of the impeller blades to rotate the water, the water thrown, so as to achieve the purpose of delivery, impeller vane made of stainless steel stamping welding, with long axis motor, shaft To the entrance and radial exit. It can deliver clean water or other liquids with physico-chemical properties similar to water.

Horizontal multi-stage centrifugal pump disassembly order:

1, choose tools, (F wrenches, pipe wrenches, openings, a set of wrenches each, a 300 mm wrench, washing basin, crowbar, copper rod, flat screwdriver, Rally, cotton yarn, hand hammer, , Sandpaper, file, empty barrel butter, vernier caliper, micrometer, acupuncture, thermometer, amplitude meter) the choice of tools and flexible use.

2, Oral: (stop the unit according to the normal procedure, wear insulated gloves to pull off the knife, cut off the maintenance warning signs, close the pump inlet and outlet valves to vent, blowdown, remove the motor lead, remember the phase sequence, Shaft guard, remove motor anchor bolts, remove motor by 90 degrees.

3, first of the oil in the tank to vent, remove the coupling with a tensioner, remove the button, remove the cover bolts evenly, remove the pump bracket bolts, smooth down the pump body, on the sleepers, remove the impeller back Cap symmetry pry down the impeller, into the wash basin, remove the root gland screws, remove the pump cover and bearing housing connection bolts, the pump cover symmetry pry removed, remove the old packing and water seal ring, packing Gland, retaining ring, remove the bearing housing front and rear bearing cap bolts, remove the cap, remove the pump shaft and bearing connections, using a power take off the bearing, the removal of all pump cleaning and inspection.

Select horizontal multistage centrifugal pump material, 9 steps easily get:

Electrochemical corrosion

In order to prevent the medium from electrochemical reaction, the horizontal multistage centrifugal pump generally chooses the same material.

2. Medium temperature

For high temperature environment and the use of low-temperature environment of the pump material is not the same, because creep at high temperatures, brittle at very low temperatures generally have corrosion-resistant materials at room temperature under high temperature may not necessarily have corrosion resistance The ability of high temperature, so the material properties should meet the requirements of the temperature of the medium delivered.

3. For single stage high lift

High-speed single-stage pump corresponding to the liquid flow rate is high, for the flow of components need to choose strong anti-cavitation performance, erosion resistance and good performance.

4. Wear of solid particles

For media containing abrasive solid particles need to select the material with strong wear resistance.

5. Bite between materials

For the shaft sleeve, bolts and nuts, impeller seal ring and the pump body seals and other relative movement of the parts, the choice of materials should make the two parts of the hardness difference between the materials to avoid handling and operation in the easy to bite or scratch each other .

6. The same part of the size of the temperature difference

When the same part of the work temperature difference is large, such as pump high temperature liquid cooling plus cover, pump cover and the media contact at high temperature expansion of large contact with the cooling water temperature low expansion, such parts should adopt plasticity Good material, so as to avoid running due to the expansion of different cracks.

7. Parts to be welded

In the casting, processing and use of the parts need to repair welding application of good welding materials, such as low carbon steel weldability than high carbon steel weldability.

Economic

The material is not the same, the corresponding performance is not the same, the corresponding product prices are not the same, so at the same time several materials can meet the requirements of the case, the corresponding price to choose a relatively favorable, but the product parts and components are compared technology and quality Ok.

Corrosive media

Different material corrosion resistance is not the same, such as 1Cr18Ni9 resistant to medium and thin concentrations of nitric acid or organic acid corrosion, but not resistant to dilute sulfuric acid, hydrochloric acid corrosion, fluorine plastic material can be used to a variety of acids and bases.

China haina pump Horizontal multistage centrifugal pump is widely used in power plant, building and living. With the development of industry and the advancement of technology, the single-stage centrifugal pump has been unable to meet the new technological requirements gradually. Multistage centrifugal pump starts in this situation Rise. Horizontal multi-stage centrifugal pump in the event of failure, may lead to the entire production stopped, we must make the appropriate inspection and maintenance work.